Products

Spot welding machine

What is Spot Welding? Spot Welding is mainly used in the welding of sheet metal. The resistance welding equipment for Spot Welding can be in the form of stationary or bench type welding machines, portable spot or robotic welding guns, and multi head spot welding machine designed for different applications. The recommended maximum weldable per sheet thickness for resistance spot welding is 5mm. Weldable materials include mild steel, stainless steel, galvanized steel, aluminum alloy, copper alloy, titanium alloy, high tensile steel, carbon steel etc. Generally speaking, spot welding welds one point at a time while Projection Welding welds multiple points at a time at the embossed points on the sheet metal.

View more

Projection Welding Machine

Projection welding is characterized by joining the predetermined weld point or so called projections or embossments on the weld part with the parent material. Projection welding current and weld force are localized on the weld points unlike spot welding where the weld is determined by the size or shape of electrode. Projections for projection welding can be produced by embossing on sheet metal, machining or cold forging on a solid piece and press punch on the edge of a piece. Projection welding has wider applications than spot welding; from welding nuts and bolts to sheet components to as big as welding bearing bars and cross bars to form a grating panel. To know more about what a projection welding machine is and how it can be applied for, please check out this article.

View more

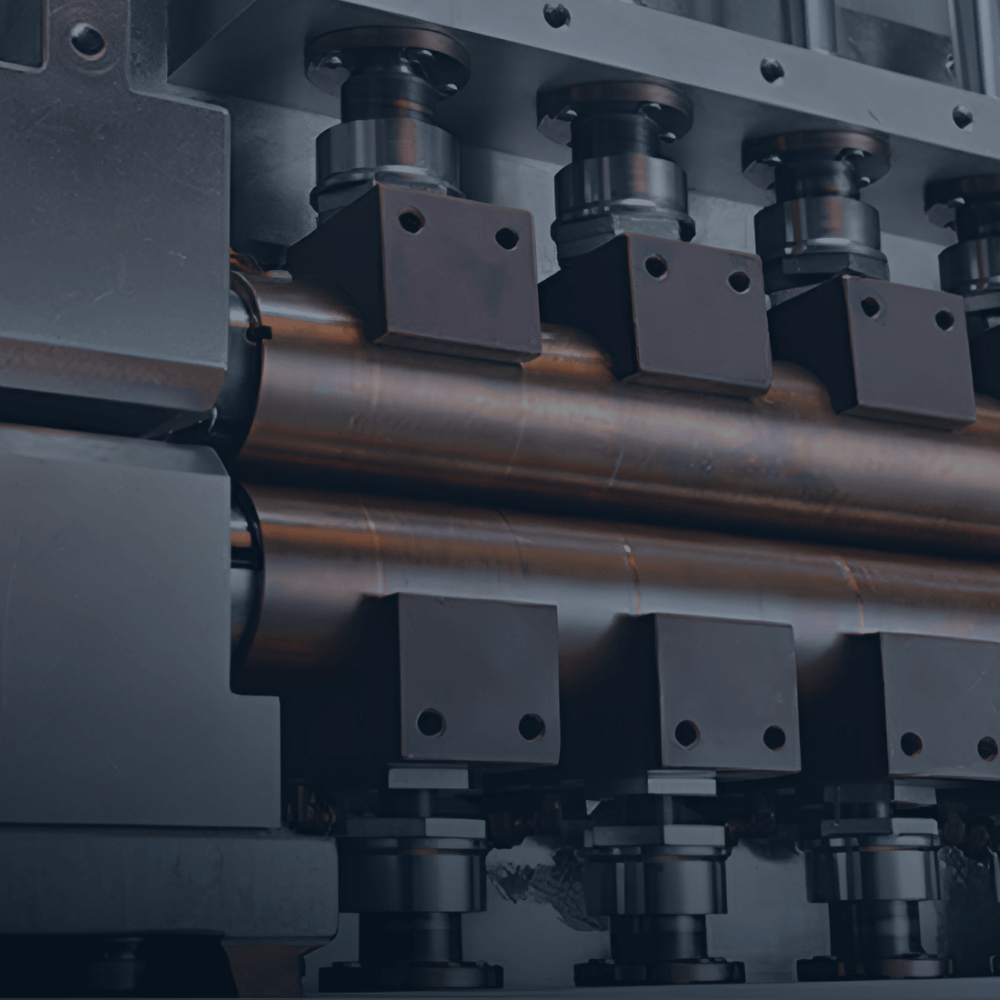

Seam Welding Machine

Unlike Spot and Projection welding which is static welding, Seam welding is welding through motion. One or two wheels rotate to make a series of overlapping spot welds on sheet components to achieve air or liquid proof on the welded part. There are Roll Spot and Seam in seam welding. Roll spot are an interchange between a spot or a series of spot welds and a period of cool time but without opening the electrode during the welding process. Roll spot is well depicted in the brake shoe seam welding process where the embossments on the rim are roll spot welded. Seam in seam welding separates into continuous seam and pulse seam. Continuous seam is overlap of spot welds without cool time while pulse seam is overlap of spot welds with cool time but so short that the spots are still connected together. Both continuous seam and pulse seam sometimes can run on same machine. The selection between continuous seam and pulse seam can be decided based on the sheet component material and the weld appearance. The seam welding machine also has Internal and External cooling on the electrode wheels. Selection between Internal and External cooling on seam welding vary among sheet component material, weld strength to be achieved and application of the weld part. You can get more information about our seam welding machines by clicking the images below. To know more about what a seam welding machine is, please check out this article.

View more

Butt / Flash Butt Welding Machine

Flash Butt Weld / Butt Weld is a resistance welding that does not require overlap of weld material. It is commonly used to join same or different cross section in tube, bar, rod, sheet or plates. Butt weld is also called Upset weld. Heat for welding is the resistance to electric current created through contacts between the moveable part and the fixed part. As the weld part touches, the material starts to flash and sparks (metal loses) from the weld area. The flashing process heat up the cross section of the weld part, then comes the butt weld (Upset) process. Upset process is to accelerate the movable part towards the fixed part with higher current. Rapid speed and continuous pressure will weld two pieces together. Check out our flash butt welding machine and butt welding machine below. Frequently Asked Questions

View more

Heating & Fusing Machine

Resistance Heating machine is to generate heat on metal part by utilizing resistance welding electrical system. Upsetting is to apply force to the resistance generated heat zone to forge the metal part to shape. Refer to the Heating and Upsetting product section to find out more.

View more